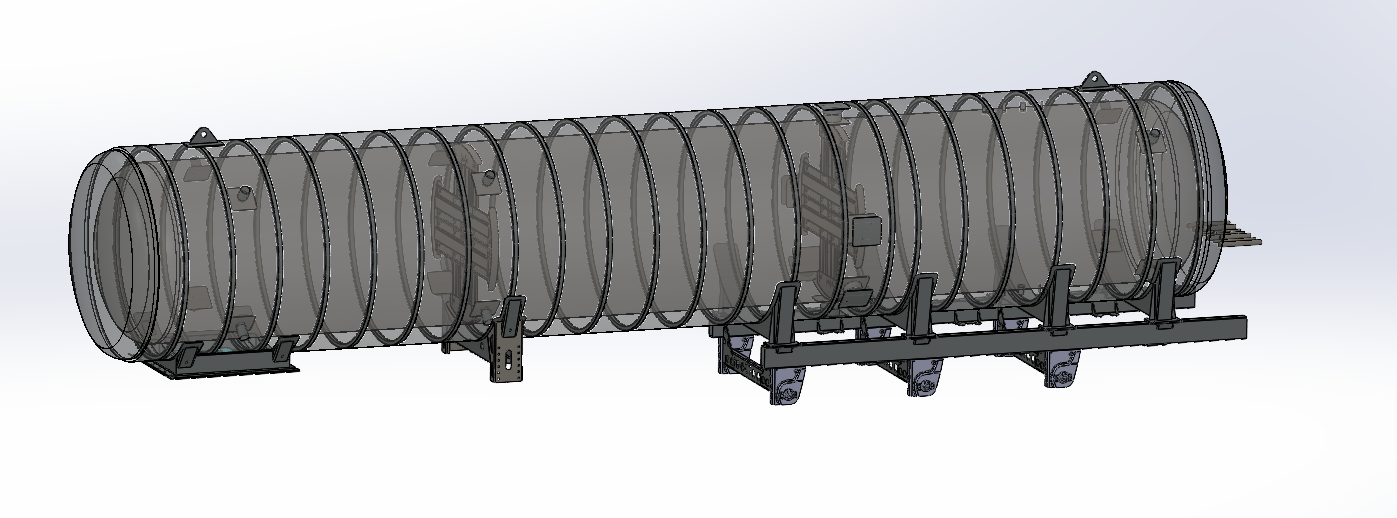

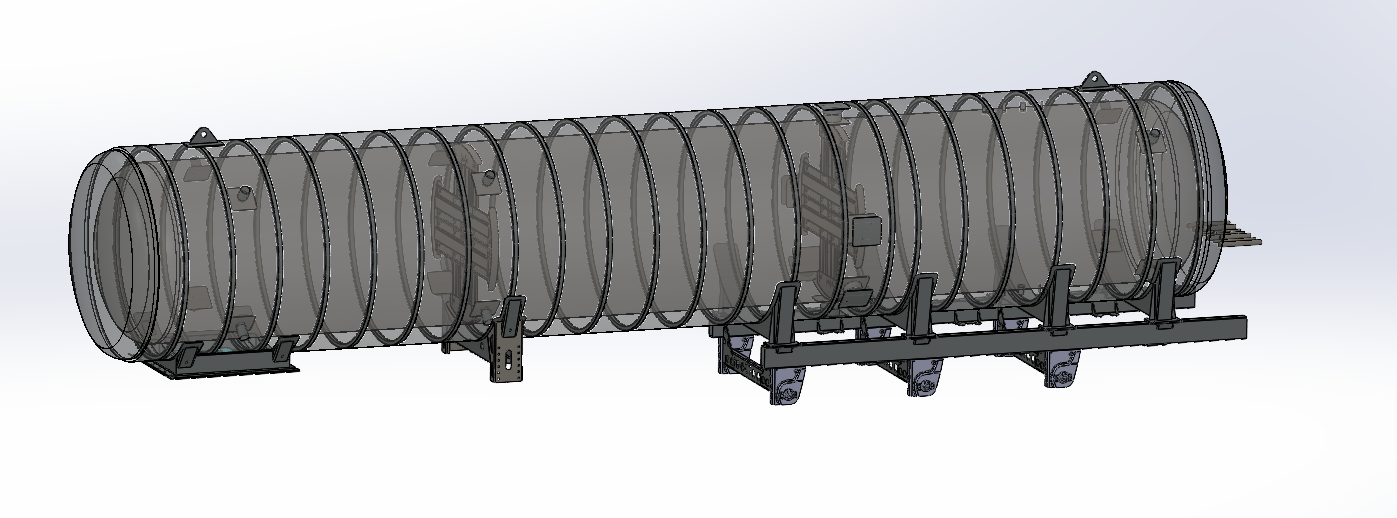

FEATURES OF HARSAN TANKS

- Compliant with EN 13530, TPED, and ADR regulations and standards.

- π Certificate obtained.

- Special design tailored for the efficient transport of Cryogenic Liquids at maximum capacity.

- Utilizes a cutting-edge Lamination System.

- Sheet thicknesses are optimized through meticulous calculation, and the product weight is significantly reduced with the latest technology lamination system compared to standard materials.

- The application of a sunshade on the tank contributes to lowering the temperature at which the tank surface is affected.

This design emphasizes compliance with industry regulations, certification, and the utilization of advanced technologies to enhance efficiency, reduce weight, and minimize temperature impact on the tank surface.

APPLICATION AREAS

Transport tanks for LIN, LOX, and LAR are used in the transportation of cryogenic liquids. These tanks are vital for industries involved in gas distribution, metal fabrication, and healthcare, ensuring the safe and reliable delivery of liquid nitrogen, oxygen, and argon.

GENERAL FEATURES

TYPE | TRANSPORT |

DESIGN STANDARDS | EN 13530 – TPED – ADR |

MEDIUM | LIN – LOX – LAR |

DESIGN PRESSURE | 5 BAR – 17 BAR |

DESIGN TEMPERATURE | -196 °C / +50°C |

VOLUME | 1M3 – 55M3 |

INSULATION | SUPER INSULATION + VACUUM |

TANK BODY EQUIPMENT

Filling / Discharging Line:

Standard LIN-LOX-LAR filling and discharge openings equipped with cryogenic ball valves in the installation cabinet.

Discharge Pipes:

Discharge pipes extend from foot valves to couplings, welded to patent elbows, certified to ISO 3834 Welded manufacturing quality qualification.

Filling/Discharge Globe Valves:

1 ¾”, 1 ½, and 2” cryogenic ball valves (HEROSE-REGO) installed in the plumbing cabinet, at the gas and liquid line ends.

Emergency Shutoff Valves:

1 ¾”, 1 ½, and 2” Cryogenic globe valves (HEROSE-REGO) for emergency shutoff.

Safety Relief Valves:

Safety valves (HEROSE-REGO) designed to ensure working pressure safety, surrounded by a protective pool to guard against possible impacts.

Level Gauge and Manometer:

Cryogenic liquid-compatible special production level gauge (SAMSON-WIKA) displaying tank level.

Evaporator:

Star-type special profile made from AW 6063 material.

OPTIONAL ACCESSORIES

• LIN-LOX-LAR transfer pump (CRYOSTAR 28 bar, 406 psi) (IGC 11/82 norm)

• Valve cabinet made of rust-free material

• Cryogenic Pneumatic Valve 1 ¾”, 1 ½ , 2”